A Little Re-engineering and a Lot of Collaboration

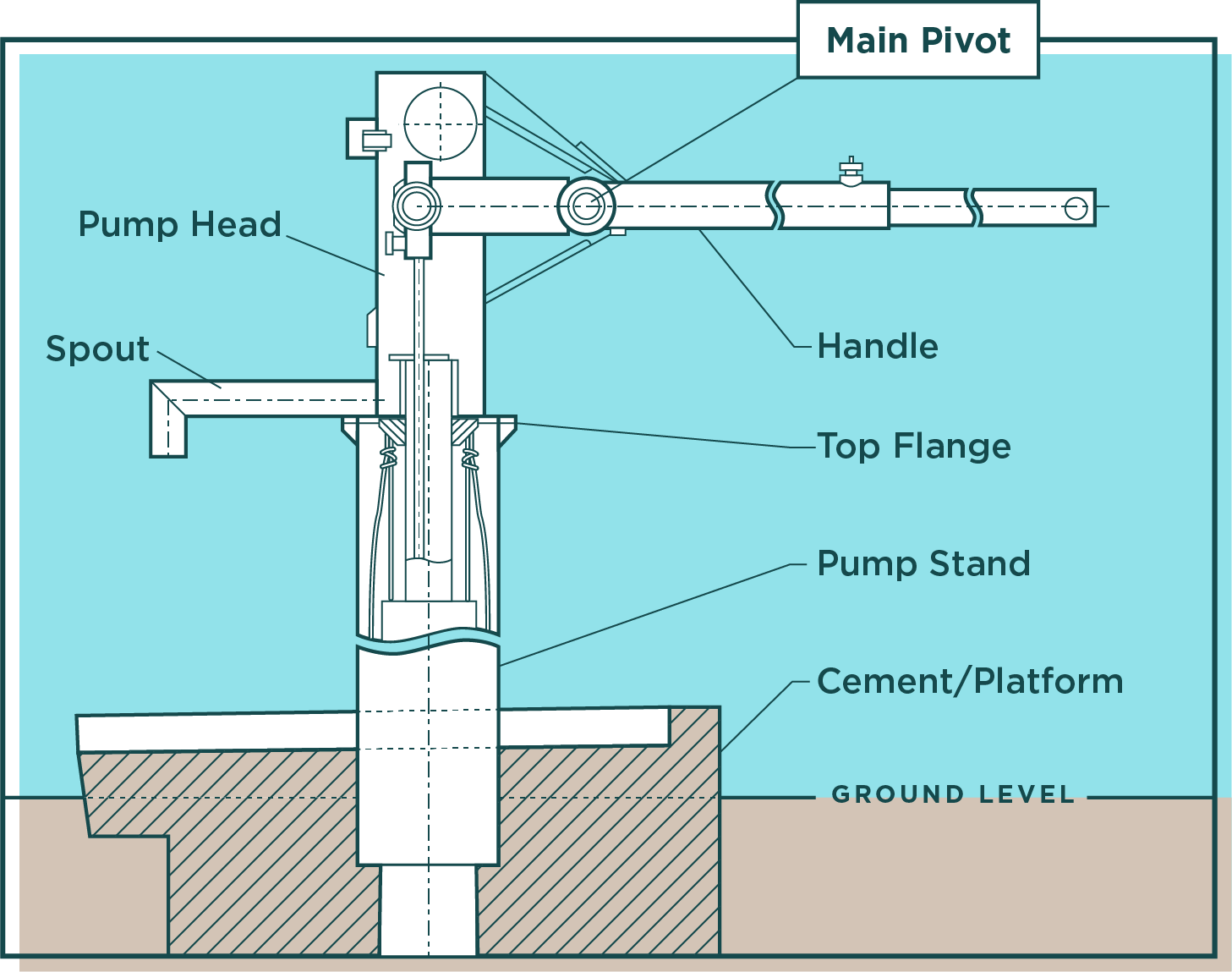

While monitoring and evaluating water sources over the past decade for African villages whose primary source of clean drinking water is a borehole with an Afridev hand pump, Engineers Without Borders Program Engineer, Gerard Dalziel, discovered as many as one-third of the pumps were broken. These Afridev water pumps can be in operation up to 12 hours a day. If the water pump fails, villagers either travel long distances to other water sources or dig an open hole to access water. These open water sources then become contaminated and unhealthy (Figure 1).

These pumps were designed in the 1980s and have undergone relatively few upgrades. What might it look like for African villagers to greatly extend the life of the ubiquitous Afridev hand pump?

Many of the pump failures involved the main pivot on the pump handle. The main pivot (Figure 2) rotates on two nylon bushings that act as bearings between the pump handle and the pump body.

These bushings are made of plastic and wear out quickly due to the repeated pumping motion of the handle. Dalziel came up with the idea of supplementing the nylon bushings with steel bearings that should last much longer in the pump than plastic bushings alone (Figure 3). However, he needed to test out his design and demonstrate the validity of the concept.

Collaboration was the key to taking the idea to the next level. First, through their senior design projects, engineering students at the Colorado School of Mines analyzed and tested the proof of concept design, producing two reports showing that the steel bearings should easily outlast the plastic bushings.

Then, with the support of a Posner Center International Collaboration Fund grant, the team developed a pump retrofit installation kit with the steel bearings and installed them at six active water pump sites in communities in Zomba District in Malawi. Freshwater Project International, an organization that supports school and healthcare center water projects, provided on-the-ground installation, training, and ongoing performance monitoring during the field test cycle (Figure 4).

After six months of use in Malawi communities, the prototype retrofit kits will be retrieved, and wear and tear on the bearings will be evaluated on precision measuring equipment at the Colorado School of Mines. If wear is minimal, this simple innovation—a steel replacement for the main pivot point of the pump—has the potential for scalability and provides a modern upgrade to an important source of water for rural communities across Africa and the Middle East.

According to Heidi Rickels, co-founder of Freshwater Project International, “If we succeed at extending the life of these bearings to reduce maintenance requirements in remote villages, it could be a game changer for community water supplies.”

It won’t be easy. Scaling will involve design refinements for ease of manufacture and cost reduction, sourcing, supply chain, and deployment decisions. As with the design and testing phases, collaboration with manufacturers and other organizations working in the WASH sector in Africa will be vital to the speed of entry, quality, sustainability, and overall success of this emerging idea.

If field testing is successful, Engineers Without Borders will be working to secure funding and partnerships for production and go-to-market activities. This work includes exploring local capacity with machine shops and parts suppliers in Malawi.

Going forward, access to this small steel bearing could help keep clean water flowing in hundreds of thousands of communities without having to replace expensive pumps.

“In order to bring this pump improvement to these communities, we will need continued, on-the-ground collaboration with multiple, actively engaged partners,” said Dalziel.

Collaborators

Engineers Without Borders harnesses the skills of engineers to tackle the challenges that keep the world’s poorest people from living healthy, productive lives.

Freshwater Project International provides clean water, sanitation and hygiene (WASH) facilities to people in villages, schools, and health centers in Malawi, Africa.

Colorado School of Mines is a public research university focused on science and engineering, where students and faculty together address the great challenges society faces today—particularly those related to the Earth, energy, and the environment.